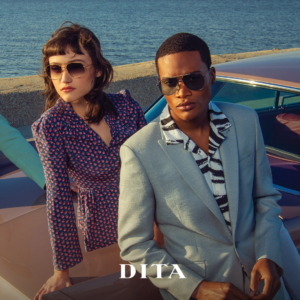

DITA

Master Craftsmanship – Each Frame Takes Many Months to Create – Handmade in Japan

Founded in 1995, DITA reinvented eyewear by transcending its conventions, creating a discreet luxury with product ranging from bold character frames to new interpretations of timeless shapes through innovative technology. With over 25 years in design and partners at the highest levels of manufacturing, DITA’s expertise is unparalleled, earning a coveted reputation as a true leader in optical innovation. DITA has a cult-like following and is a must-have accessory for many celebrities, musicians, athletes and fashion industry insiders around the world.

DESIGN THAT FINDS BEAUTY IN PURPOSE.

Focus. Discipline. Time. Sacrifice. Failure. Success. Qualities that make the ordinary extraordinary, which is why each design is treated independently, taking months from conception to production.

TITANIUM PRODUCTION

DITA uses one of the highest grades of beta-titanium, which is thin, durable and extremely flexible. Our beta-titanium is 1/3 the weight of steel.

ACETATE FINISHING

Our acetate frames use a proprietary tumbling process to achieve their beautiful finish. DITA uses some of the highest quality acetate available.

HINGE SYSTEM

Designed with parts that are removable and replaceable, DITA uses assembled hinges for ultimate longevity.

OPTICAL COATINGS

All lenses feature AR (anti-reflective) coating which reduces glare on the back of lenses, gradients, mirrors, and flashes. An additional chemical hard coat increases scratch resistance and improves cleaning and durability.

OVER 25 YEARS OF HERITAGE

For more than 25 years, our focus has been one thing: perfecting the art of eyewear. We aren’t a fashion house license. We are specialized.

CRAFTSMANSHIP THAT CELEBRATES THE UNSEEN.

Craftsmanship is the cornerstone of DITA’s reputation for quality and innovation – that’s why our relationships with some of the world’s most highly regarded artisans have lasted not years, but decades.

PRESERVING THE PRECIOUS

DITA’s relationships with some of the world’s most highly regarded artisans in eyewear have lasted not years, but decades. Those relationships continue until this day.

JAPANESE QUALITY

We finish all our frames in Japan. Not because we can, but because we must. Because the level of detail in our frames requires the utmost level of quality, and that quality is found in Japan

A CRAFT THAT TAKES MONTHS

DITA’s manufacturing standards and specialty design language require months to craft a single frame.

DITA SALES POLICY

Repairs Offered – Brenart Eye Clinic and DITA will stand behind their products, so any issue that comes up please bring them to our optical department. We will take pictures of the issues and send them to DITA service department via email. They will then notify us within 48 hours of how to proceed. In some cases, they can send the parts to Brenart Eye Clinic to be repaired at our office, or they may request you to allow us to send in your frames for repair to their lab – allowing their talented craftsman to repair them. In most situations, they will come back looking brand new. The process typically takes about 10-14 business days. If DITA feels that the defect or damage is not due to normal wear and tear or manufacturer defect, there may be a charge to the consumer. DITA sales at Brenart Eye Clinic are final. Due to the quality and craftmanship of these frames, they are unable to be exchanged or returned.